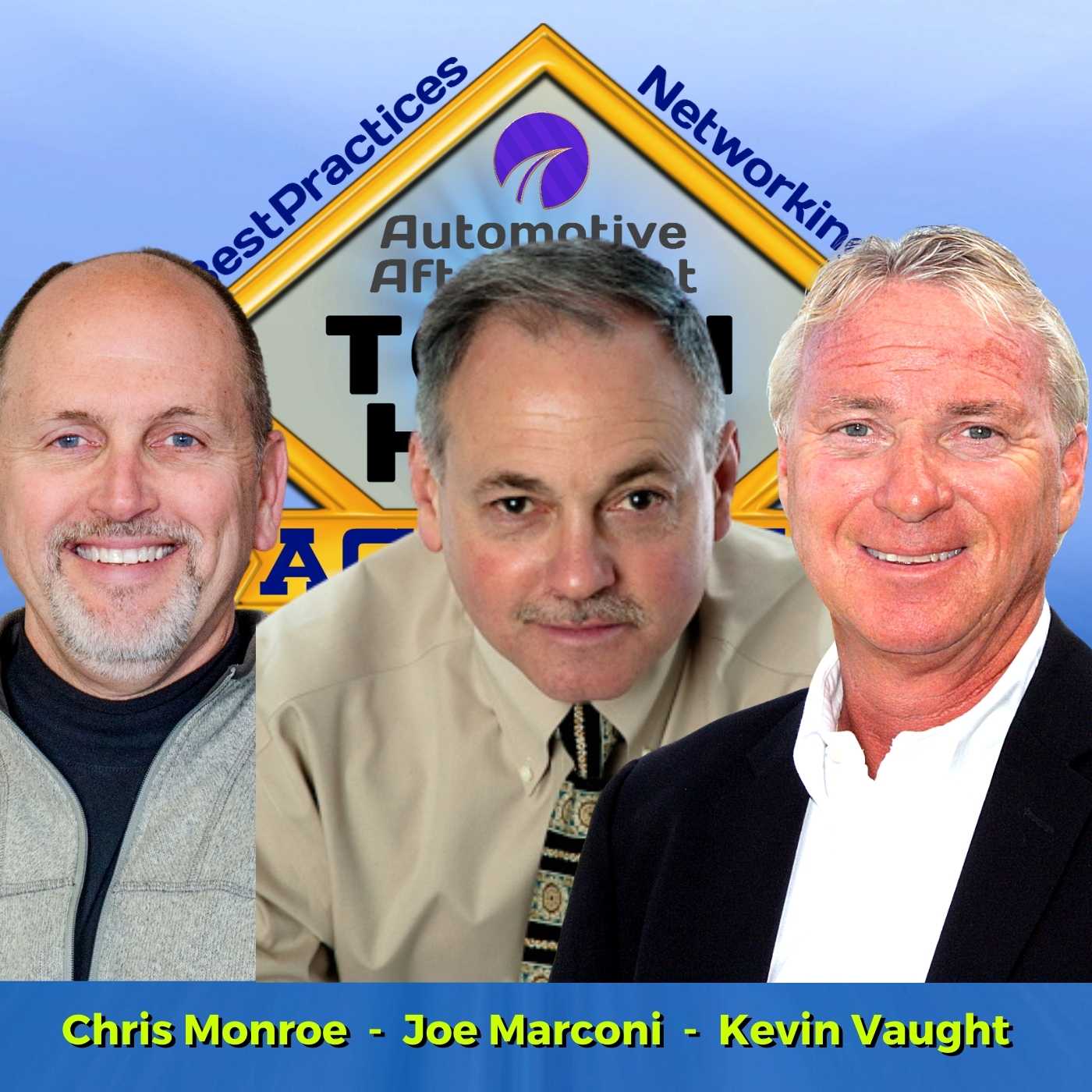

Creating the Right Environment for Shop Efficiency [THA 201]

https://youtu.be/d-XvgyKBp7g Chris Monroe, Monroe Tire & Service, Shelby, NC (Elite Coach) Joe Marconi, Osceola Garage, Baldwin Place, NY (Coach with Elite Worldwide) Kevin Vaught, Elite Worldwide Business Development Coach, former multi-shop owner Key Talking Points: Chris Monroe How are we making our service departments more efficient through better communication and organization? Equipment Location- why is it located where it is? Digital paralysis...do we get so focused on technology that we lose the basics? Being able to recognize basic pain points and saluting them Inventory-labeled and organized Radios-bring the conversation in close-save steps Process-from when the customer walks in, to check out....making the process slick. What is working? The problem is...shop owners have trouble seeing stupid stuff with clean eyes. Solutions are typically simple and cheap. Who is working on taking steps out of the process? Joe’s Marconi (A different perspective - I am sure we will cover shop layout, Digital MPI, tools, equipment, etc.) It all starts with the right people. The stronger the team, the more potential for high efficiency and production. No amount of technology will ever take the place of people. Before you look to technology to solve problems with production, get your house in order with regard to the right people, culture and morale. Leadership is key – MBWA- Management By Walking Around. Encourage your people, recognize the right behavior, give them praise, give them feedback. Celebrate wins and promote self-direction. Cultivate leaders within your company. Every aspect of the workflow needs to be reviewed often, refined and corrections made. To attain high efficiency requires an ENTIRE team effort. From where the customer parks the car, to effective write-up, dispatch, technician’s repair process, sales, quality control (and reducing comebacks), car delivery and follow up. Kevin Vaught Recognizing the Problem-Stepping Back-Too close to the Forest to See the Trees! (recent example to share) Observing your team and how they function with existing resources both digital and physical-align the right person with the right job Balanced inventory-better utilizes space/cash-opens up possibilities for more efficiency. Example: too many tires in stock-make space-reallocate equipment/resources to become more efficient-Tire Install Room Key drop was fashioned with a hole in the wall..nice exterior and the keys just sort of fell into this in-between space that required lots of digging Centralize equipment-prep processes Ex: Oil drains, flush equipment- Fill Jugs Tools/supplies at balancer-at aligner (sounds simple, but are you doing it) Radio's were our biggest communication slam dunk Digital tabs...are they saved for quick access along with functional terminals Internet service...is it robust enough to carry a signal without getting dropped Bottlenecks-we have a plan to install another road force Tablets instead of paper-our technicians now have in their hands mounds of information AND can push that to the right bucket in a timely manner SMS organization with canned job efficiency Parts inflow/outflow-returns-establish weekly process to eliminate backlogs SMS-fed by Insipely-DOT-AutoText-Alldata-Identifix-Mitchells-Carfax-Website parallels-TPMS resources/tooling (9) Tab Organization on each terminal-no matter which terminal, consistent lookup locations that save time Resources: A special thanks to Chris Monroe, Joe Marconi, and Kevin Vaught for their contribution to the aftermarket. Books Page https://my.captivate.fm/books/ (HERE) Listen to all https://remarkableresults.biz/remarkable-results-radio-podcast/ (Remarkable Results Radio), https://remarkableresults.biz/for-the-record/ (For The...